You are here

Contract Manufacturing Services

Haala Industries has been providing the highest quality metal fabrication services for nearly half a century, and we continue to innovate! We are pleased to offer expanded services and capabilities for your contract manufacturing needs.

Do you have parts or components that you don't have the time or resources to produce in-house? Put Haala's experienced designers, fabricators and machinists to work for you. We can provide the products you need to meet your exact specifications and keep your operations on schedule.

We operate out of a modern, 160,000 sq ft. facility that has been updated with state-of-the-art equipment.

We Can Make It

We can produce a wide range of products from small components to large complex assembled products.

- Long-Formed Channels

- Cut and formed brackets

- Panels

- Motor mounts

- The options are limitless

Haala Equipment Capabilities

-

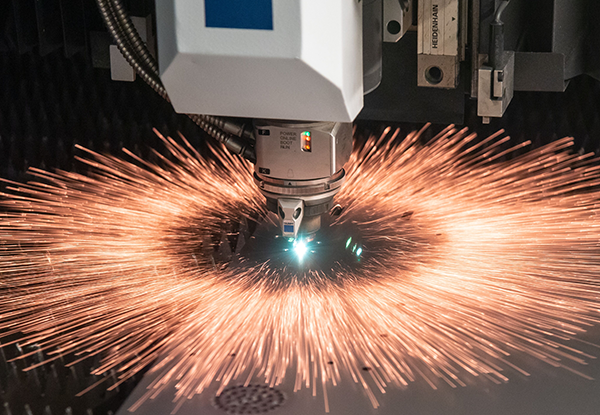

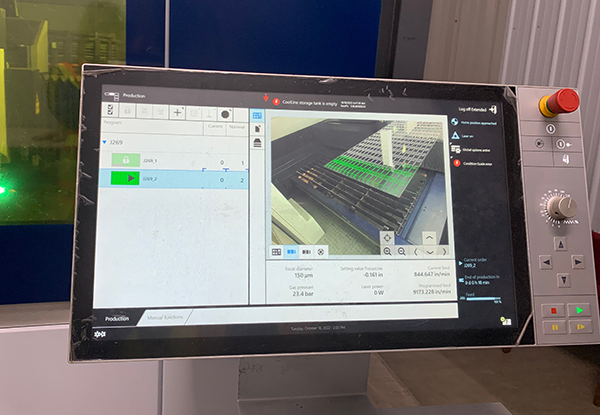

Trumpf Fiber Laser 5060 with 12KW of cutting power

- 6′x20′ cutting table

- Up to 1.375″ Stainless Steel and 1.25″ steel material

- Can also cut brass, aluminum, and copper

-

Trumpf Press Brakes Tandem 8320

- 700 tons bending force over full length of bed

- 20′ total bed length

- Tandem operation for processing two individual jobs simultaneously or one large job

- Offline programming for tooling calculations

-

Two Alltra plasma tables

- 72″x144″ cutting table

- 72″x192″ cutting table

- 275 Amp power supply pierces 1.5″ material and edge cuts 2.5″

-

Marvel vertical bandsaw

- 15″x20″ capacity

- Auto bevel cutting up to 60 degrees left or right

- Auto feed table with back feed option

-

Three Tesker bar roll threaders

- Up to 1.5″ diameter threading capacity

-

Four Genesis robot cells with Fanuc welding arms

- 6′x12′ table capacity

-

Baileigh 3-roll bar roller

-

Plate roller

- 6′ x 1/4″ capacity

-

Plus many shears, presses, drills, iron workers, and tube/pipe benders.

-

Experienced Team

- Certified welders

- D1.1 certifications for unlimited thickness

- D1.2 certifications up to 3.4″ material

-

In-house design services using Solidworks

- Can import many other 2D or 3D file types

-

Outside services

- Galvanizing to ASTM A123 up to 50′ long

- Galvanizing to ASTM A153/F2329

- Powder coating up to 50′ long

- Machining

With our extensive metal fabrication know-how and lean manufacturing practices, we can help you increase efficiency with reduced labor and equipment costs and give you more time to win more business.

To learn more, contact our Contract Manufacturing Leader:

Caleb Siefkes

Phone: 507‑240‑1520

eMail: caleb.siefkes@afinitas.com